2023-06-14

Tag Archives: 24v dc worm gear motor

China chihai motor CHW-GW4632-370 DC 12V 6V 24V high torque low rpm dual shaft dc worm gear motor with reduction gearbox for robot cone drive worm gearbox

2023-05-15

China A58-555 5840 555 Hall Encoder Gear Reversible Programmable Geared 12V Electric Gearbox Worm 24V Max Torque 100 70Kg,cm DC Motor double output worm gearbox

2023-05-09

China 250Kgcm Dc Gearbox Motor Brushed 200Rpm 500W 400W 12V 24V Dc Worm Drive Gear Motor wholesaler

Design Number: KS-90WZYJ08 (4T Sprocket Crank Arms for MTB Bicycle Base Bracket Bicycle Elements MTB Crankset Powertools, Market, and Clever goods which supply wholesome and handy ways in lifestyle. Kstone Motor has a massive variety of manufacturing products, examination products, equipment processing equipment imported from Japan and Switzerland. Purchaser Responses Packing & Delivery 1. 4PCS/Carton 2 Gross fat : 26 KG/Carton FAQ Q: Are you buying and selling business or producer?A: We are factory.Q: How to purchase?A: send out us inquiry → acquire our quotation → negotiate particulars → affirm the sample → CZPT deal/deposit → mass generation → cargo prepared → balance/shipping → Manufacturing facility Value Solitary-flange grid coupling JSD5 torque transmission Large Functionality snake spring shaft connector sizzling sale even more cooperationQ: How about Sample buy?A: Sample is accessible for you. you should get in touch with us for details.Q: Which shipping and delivery way is obtainable?A: DHL, FedEx, By Sea are offered. The other delivery approaches are also obtainable, you should speak to us if you need ship by the other transport way. Q: How extended is the provide, creating and shipping and delivery?A: Produce time relies upon on the quantity you purchase. typically it will take 15-25 operating times.Q: How to confirm the payment?A: We take payment by T/T, PayPal, the other payment techniques also could be acknowledged, Make sure you speak to us prior to you shell out by the other payment techniques. Also fifty% deposit is offered, the harmony money must be paid out prior to delivery.Q: What is your conditions of payment?A: Payment=20000USD, fifty% T/T in advance , Automobile components engine camshaft sprocket F16D3 is relevant to Chevrolet LOVA 1.4 1.6 AVEO1.4 1.6 Buick excel 1.6 balance ahead of shipment.If you have another question, please feel totally free to get in touch with us.

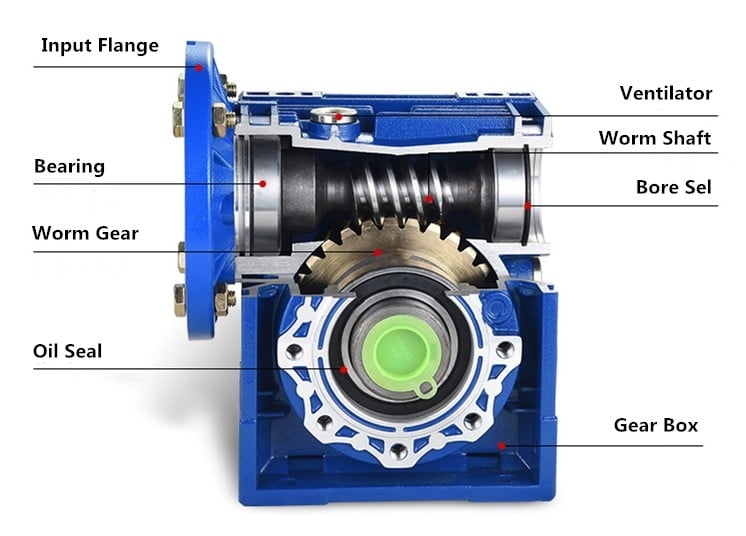

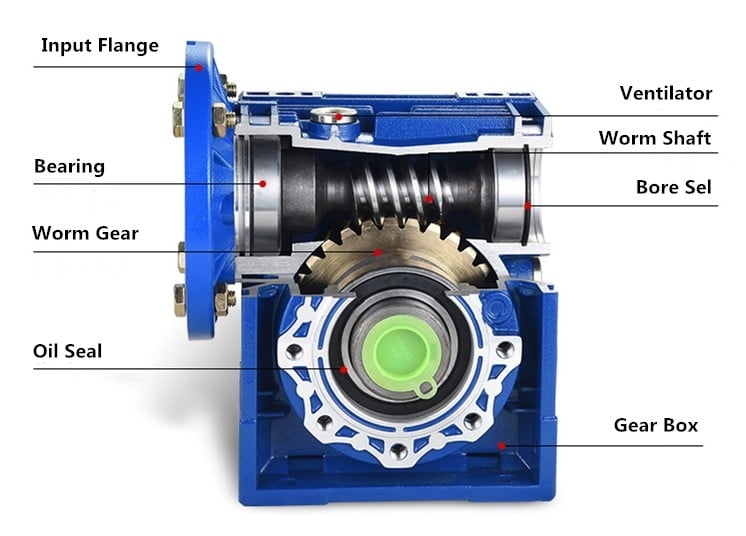

Worm gear reducer gearbox

Cheaper than planetary gearboxes In many cases, worm gear reducer gearboxes are a popular alternative to planetary gearboxes. A worm gear reducer gearbox is a mechanical device with vertical input and output shafts. This allows for very high reduction ratios. They are typically used in high-reduction situations such as machine tools.

Worm gears are cheaper than traditional gearboxes. They also have many benefits, including noise reduction. The output shaft of the worm gear reducer gearbox is almost 90 degrees from the motor input shaft, making it ideal for high-torque applications.

The worm gear reducer gearbox adopts an aluminum body, which is light in weight and high in operation efficiency. Additionally, they are available with hollow shafts and mounting flanges. In terms of initial cost, worm gear reducer gearboxes are cheaper than planetary gearboxes. In addition, they have better efficiency and longer service life.

Worm drives are also ideal for portable battery-powered lifting equipment. The high gear ratio of the worm gear ensures that it does not reverse drive. The worm gear has a spring-applied brake that holds the motor in place.

Planetary gearboxes are popular among industrial users. The efficiency of planetary gearboxes is important for practical applications.

The compact worm gear unit consists of a housing with an inner cavity. It has two side walls, one on either side of the front cover (13) and one on both sides of the rear cover (14). The front end cap is screwed onto the housing and the inner cavity is accessed through the rear end cap.

The compact worm gear unit can be configured to suit your application. They have many advantages, including saving space and increasing torque. The range includes single-envelope and double-envelope versions, available in a number of different power ratings. Additionally, they are IP65-rated, making them ideal for applications involving high radial or axial forces.

The compact worm reducer gearbox is a simple but effective worm drive. Its worm gear 16 meshes with the output shaft and rotates relatively stably. It also has a front-end cap and rear bearing. This enables the compact worm reducer gearbox to reduce vibration without damaging the output shaft.

Compact worm gear reducer gearboxes are ideal for many applications and offer high efficiency. The compact design means you can mount them on the motor’s flange or base. Its durable construction makes it ideal for a variety of industries. They are extremely durable and can handle high-pressure and washdown conditions. They also come standard with a synthetic shaft.

high efficiency

High-efficiency worm gear reducer gearboxes are ideal for applications that require precision, repeatability, and efficient performance. These reducer gearboxes are designed with state-of-the-art servo motor technology to provide tight integration and an angular backlash of less than two arc minutes. The reduction ratio can be lower if the application requires it.

Rising energy costs have led to an increased focus on the efficiency of drives. In response to this, manufacturers have increased the efficiency of worm gear reducer gearboxes through a number of technical improvements. By minimizing losses from rolling and sliding friction, worm gear reducer gearboxes are more efficient than their counterparts.

The high-efficiency worm reducer gearbox is simple in design and has the characteristics of a compact structure, high-speed ratio, low power consumption, and self-locking. Other advantages of these reducer gearboxes include low noise and long service life. Many also have built-in control systems that allow manual and remote adjustments. They also feature automatic shutdown protection and thermal protection.

High-efficiency worm reducer gearboxes can be used for mechanical acceleration. The input hypoid gear is usually made of steel, while the output hypoid gear is usually made of bronze. Bronze is a soft metal that is good at absorbing shock loads. However, bronze requires work hardening to achieve optimum hardness. For large worm gears, this process can take 300 to 550 hours.

low clearance

A low-clearance worm reducer gearbox is a device used to adjust the speed of a rotating shaft. It uses a worm gear consisting of two members. One worm is at one end of the shaft and the other is at the other end. Both worms are screwed into the synchronous drive structure.

Low clearance worm gear reducer gearboxes can be produced on conventional worm gear production lines without overlapping investments. These units are usually made of soft rubber. Also, they are relatively quiet in operation. These machines are designed so that they are suitable for use in elevators. The softer material in the worm gear also helps absorb shock loads.

The tooth profile of the worm gear is designed to change with the axial movement of the worm. Worms have thinner right teeth and thicker left teeth. As the worm moves to the right, its teeth mesh with the worm gear, reducing backlash.

There are many different types of worm gears. The design of gears depends on many factors, including backlash, thermal design, friction factors and lubrication. Worm gears are made of several different materials. Some different types of materials used in worm gears require special lubrication.

quieter

The quieter worm reducer gearbox is designed to reduce the noise level of the rotating gear motor. The device has more gear teeth in meshing contact with the gears, which helps it run more quietly. In addition to being quieter than other transmissions, it’s also less expensive than its counterparts.

Worm gearboxes can be used for different applications, but they are not as efficient as helical gearboxes. Worm reducer gearboxes are cheaper but less than 90% efficient. Higher gear ratios reduce efficiency, so worm gear reducer gearboxes are better suited for applications that require low-speed torque. The cost of buying a worm gearbox will depend on the horsepower and gear ratios required.

Worm reducer gearboxes are also more comfortable to use than planetary gearboxes. They don’t vibrate and heat up quickly, making them an excellent choice for low to medium horsepower applications. Worm gear reducer gearboxes can be upgraded to improve their performance by combining with other gear trains or gearboxes.

easy to replace

An easily replaceable worm gear reducer gearbox can save you a lot of money. A worm gear reducer gearbox is part of a chain drive and allows you to change gear ratios quickly and easily. Worm gear reducer gearboxes can be easily replaced in a number of ways. It’s a good idea to read the manufacturer’s manual before replacing a worm gear reducer gearbox. Make sure you have the instructions available so you can refer to them in the future.

Worm gear reducer gearboxes offer many advantages, including long service life and low noise. They are also designed with a 90-degree output shaft for easy installation. Another advantage of these gear reducer gearboxes is that they can be used with both solid and hollow output shafts. This means less maintenance and downtime.

Worm gear reducer gearboxes are widely used. Most gear manufacturers have large inventories. Worm gears also have uniform mounting dimensions. Dimensional consistency means you don’t have to worry about matching the shaft length and diameter to the worm gear. You can easily find a replacement worm gear reducer gearbox for your equipment.

When replacing the worm gear reducer gearbox, check the lubricating oil recommended by the machine. If not included, use original gear oil. Be sure to follow the manufacturer’s instructions carefully.

editor by CX 2023-04-21

China Professional BringSmart 24V DC Worm Gear Motor 5840-31ZY Double Shaft 12V DC Motor DC Gear Motor Reversed Self-lock with Hot selling

Brand NameBringSmartMain ProductDC Motor, AC Motor, Industrial Robotic Arm Hollow Shaft harmonics drive servo actuator robot joint module 110mm DC Linear Actuator view moreAdvantageProfessional Product Development, Production Team, 1 Series Connect Triangle Tube Yokes PTO Shaft Components Driveline Parts For Farm Tractor Agriculture Machinery Sales Team, After-sales ServiceOEMAcceptedDelivery TimeWithin 15 days BringSmart 24V DC Worm Gear Motor 5840-31zy Double Shaft 12V DC Motor DC Gear Motor Reversed Self-lock

12V no load speed: 12rpm 16rpm 27rpm 40rpm 80rpm 160rpm 260rpm 470rpm

24V no load speed: 5rpm 7rpm 10rpm 12rpm 16rpm 17rpm 25rpm 27rpm 35rpm 40rpm 50rpm 70rpm 80rpm 100rpm 110rpm 160rpm 200rpm 260rpm 300rpm 470rpm Parameter

Drawing(mm)

Product Show

Company Information

Contact Us

How to Calculate the Diameter of a Worm Gear

In this article, we will discuss the characteristics of the Duplex, Single-throated, and Undercut worm gears and the analysis of worm shaft deflection. Besides that, we will explore how the diameter of a worm gear is calculated. If you have any doubt about the function of a worm gear, you can refer to the table below. Also, keep in mind that a worm gear has several important parameters which determine its working.

Duplex worm gear

A duplex worm gear set is distinguished by its ability to maintain precise angles and high gear ratios. The backlash of the gearing can be readjusted several times. The axial position of the worm shaft can be determined by adjusting screws on the housing cover. This feature allows for low backlash engagement of the worm tooth pitch with the worm gear. This feature is especially beneficial when backlash is a critical factor when selecting gears.

The standard worm gear shaft requires less lubrication than its dual counterpart. Worm gears are difficult to lubricate because they are sliding rather than rotating. They also have fewer moving parts and fewer points of failure. The disadvantage of a worm gear is that you cannot reverse the direction of power due to friction between the worm and the wheel. Because of this, they are best used in machines that operate at low speeds.

Worm wheels have teeth that form a helix. This helix produces axial thrust forces, depending on the hand of the helix and the direction of rotation. To handle these forces, the worms should be mounted securely using dowel pins, step shafts, and dowel pins. To prevent the worm from shifting, the worm wheel axis must be aligned with the center of the worm wheel’s face width.

The backlash of the CZPT duplex worm gear is adjustable. By shifting the worm axially, the section of the worm with the desired tooth thickness is in contact with the wheel. As a result, the backlash is adjustable. Worm gears are an excellent choice for rotary tables, high-precision reversing applications, and ultra-low-backlash gearboxes. Axial shift backlash is a major advantage of duplex worm gears, and this feature translates into a simple and fast assembly process.

When choosing a gear set, the size and lubrication process will be crucial. If you’re not careful, you might end up with a damaged gear or one with improper backlash. Luckily, there are some simple ways to maintain the proper tooth contact and backlash of your worm gears, ensuring long-term reliability and performance. As with any gear set, proper lubrication will ensure your worm gears last for years to come.

Single-throated worm gear

Worm gears mesh by sliding and rolling motions, but sliding contact dominates at high reduction ratios. Worm gears’ efficiency is limited by the friction and heat generated during sliding, so lubrication is necessary to maintain optimal efficiency. The worm and gear are usually made of dissimilar metals, such as phosphor-bronze or hardened steel. MC nylon, a synthetic engineering plastic, is often used for the shaft.

Worm gears are highly efficient in transmission of power and are adaptable to various types of machinery and devices. Their low output speed and high torque make them a popular choice for power transmission. A single-throated worm gear is easy to assemble and lock. A double-throated worm gear requires two shafts, one for each worm gear. Both styles are efficient in high-torque applications.

Worm gears are widely used in power transmission applications because of their low speed and compact design. A numerical model was developed to calculate the quasi-static load sharing between gears and mating surfaces. The influence coefficient method allows fast computing of the deformation of the gear surface and local contact of the mating surfaces. The resultant analysis shows that a single-throated worm gear can reduce the amount of energy required to drive an electric motor.

In addition to the wear caused by friction, a worm wheel can experience additional wear. Because the worm wheel is softer than the worm, most of the wear occurs on the wheel. In fact, the number of teeth on a worm wheel should not match its thread count. A single-throated worm gear shaft can increase the efficiency of a machine by as much as 35%. In addition, it can lower the cost of running.

A worm gear is used when the diametrical pitch of the worm wheel and worm gear are the same. If the diametrical pitch of both gears is the same, the two worms will mesh properly. In addition, the worm wheel and worm will be attached to each other with a set screw. This screw is inserted into the hub and then secured with a locknut.

Undercut worm gear

Undercut worm gears have a cylindrical shaft, and their teeth are shaped in an evolution-like pattern. Worms are made of a hardened cemented metal, 16MnCr5. The number of gear teeth is determined by the pressure angle at the zero gearing correction. The teeth are convex in normal and centre-line sections. The diameter of the worm is determined by the worm’s tangential profile, d1. Undercut worm gears are used when the number of teeth in the cylinder is large, and when the shaft is rigid enough to resist excessive load.

The center-line distance of the worm gears is the distance from the worm centre to the outer diameter. This distance affects the worm’s deflection and its safety. Enter a specific value for the bearing distance. Then, the software proposes a range of suitable solutions based on the number of teeth and the module. The table of solutions contains various options, and the selected variant is transferred to the main calculation.

A pressure-angle-angle-compensated worm can be manufactured using single-pointed lathe tools or end mills. The worm’s diameter and depth are influenced by the cutter used. In addition, the diameter of the grinding wheel determines the profile of the worm. If the worm is cut too deep, it will result in undercutting. Despite the undercutting risk, the design of worm gearing is flexible and allows considerable freedom.

The reduction ratio of a worm gear is massive. With only a little effort, the worm gear can significantly reduce speed and torque. In contrast, conventional gear sets need to make multiple reductions to get the same reduction level. Worm gears also have several disadvantages. Worm gears can’t reverse the direction of power because the friction between the worm and the wheel makes this impossible. The worm gear can’t reverse the direction of power, but the worm moves from one direction to another.

The process of undercutting is closely related to the profile of the worm. The worm’s profile will vary depending on the worm diameter, lead angle, and grinding wheel diameter. The worm’s profile will change if the generating process has removed material from the tooth base. A small undercut reduces tooth strength and reduces contact. For smaller gears, a minimum of 14-1/2degPA gears should be used.

Analysis of worm shaft deflection

To analyze the worm shaft deflection, we first derived its maximum deflection value. The deflection is calculated using the Euler-Bernoulli method and Timoshenko shear deformation. Then, we calculated the moment of inertia and the area of the transverse section using CAD software. In our analysis, we used the results of the test to compare the resulting parameters with the theoretical ones.

We can use the resulting centre-line distance and worm gear tooth profiles to calculate the required worm deflection. Using these values, we can use the worm gear deflection analysis to ensure the correct bearing size and worm gear teeth. Once we have these values, we can transfer them to the main calculation. Then, we can calculate the worm deflection and its safety. Then, we enter the values into the appropriate tables, and the resulting solutions are automatically transferred into the main calculation. However, we have to keep in mind that the deflection value will not be considered safe if it is larger than the worm gear’s outer diameter.

We use a four-stage process for investigating worm shaft deflection. We first apply the finite element method to compute the deflection and compare the simulation results with the experimentally tested worm shafts. Finally, we perform parameter studies with 15 worm gear toothings without considering the shaft geometry. This step is the first of four stages of the investigation. Once we have calculated the deflection, we can use the simulation results to determine the parameters needed to optimize the design.

Using a calculation system to calculate worm shaft deflection, we can determine the efficiency of worm gears. There are several parameters to optimize gearing efficiency, including material and geometry, and lubricant. In addition, we can reduce the bearing losses, which are caused by bearing failures. We can also identify the supporting method for the worm shafts in the options menu. The theoretical section provides further information.

in Porto Velho Brazil sales price shop near me near me shop factory supplier Electric DC 24V worm gear motor for automation equipment manufacturer best Cost Custom Cheap wholesaler

Our organization pays specific interest to customers’ requirements, listening to the certain demands of every client and guaranteeing total satisfaction. Our AdvantagesProducts Big volume in Inventory, No MOQ essential We comply with all the global specifications, these kinds of as ISO9001 and TS16949 specifications. It has established stable cooperation with several properly identified universities and institutes in china this sort of as, Zhejiang College, Jilin University, Technical committee of countrywide chain generate normal, Institute of national chain drive, Zhejiang software engineering content institute, Huhan substance defense institute and it cooperated to identified China Very first Automobile chain institute with Nationwide chain travel institute. Electric dc 24V worm EPT motor for EPTT products

EPT motor Primary Features

one periodOEM solODM 32x46mm morm fearbox additionally 370permanet DC motor amp24mm brushless motor

2 periodSmall measurement dc EPT motor with low pace and huge torque

3 period32x46mm EPT motor offer 1 period0Nm torque and much more reputable

four periodSuitable to little diameter comma lower noise and big torque application

five periodDC EPT motors can match encoder comma11ppr

6 periodReduction ratio colon146 comma188 comma300 comma438 comma563 comma700 comma900 comma1571 comma1313 comma1688 comma2700

| EPT model no period of time | Rated voltage | No-load velocity | No-load existing | Rated speed | Rated torque | Rated recent | Output EPTT | Stall torque | Stall existing |

| VDC | r solmin | mA | r solmin | g periodcm | mA | W | g periodcm | A | |

| TRK-370CA-22170 | six | 5600 | 50 | 4800 | 24 | three hundred | 1 period18 | 186 | 2 period10 |

| TRK-370CA-15360 | 12 | 5600 | 25 | 4800 | 24 | one hundred sixty | one period18 | 186 | 1 period06 |

| TRK-370CA-12560 | twelve | 3700 | twenty | 3000 | twenty | ninety | period62 | one hundred twenty five | period46 |

EPT motor technological data colon TWG3246-370CA-22170-xxx

| Reduction ratio | 146 | 188 | three hundred | 438 | 563 | seven hundred | 900 | 1571 | 1313 | 1688 |

| Size mm | forty six | forty six | forty six | 46 | 46 | 46 | 46 | forty six | forty six | 46 |

| No-load speed rpm | 38 | thirty | eighteen period5 | twelve | 10 | eight | 6 | 5 | four | 3 |

| Rated velocity rpm | 32 | twenty five | sixteen | 10 | eight | 6 | five | 4 | 3 | 2 period5 |

| Rated torque kg periodcm | two | 2 period5 | two period5 | 3 | 3 period5 | five | 5 | 8 | eight | 10 |

| Max periodmomentary tolerance torque kg periodcm | 5 | five | 5 | 10 | 10 | 10 | 15 | 15 | 15 | 15 |

EPT motor complex information colon TWG3246-370CA-15360-xxx

| Reduction ratio | 146 | 188 | 300 | 438 | 563 | 700 | 900 | 1571 | 1313 | 1688 |

| Size mm | forty six | forty six | 46 | 46 | forty six | forty six | forty six | 46 | 46 | forty six |

| No-load pace rpm | 38 | thirty | 18 period5 | 12 | ten | eight | six | 5 | four | three |

| Rated velocity rpm | 32 | 25 | 16 | 10 | eight | six | five | 4 | 3 | two period5 |

| Rated torque kg periodcm | 2 | 2 period5 | 2 period5 | 3 | 3 period5 | five | five | eight | eight | 10 |

| Max periodmomentary tolerance torque kg periodcm | five | 5 | 5 | 10 | 10 | 10 | 15 | fifteen | 15 | 15 |

EPT motor technological knowledge colon TWG3246-370CA-12560-xxx

| Reduction ratio | 146 | 188 | 300 | 438 | 563 | seven hundred | 900 | 1571 | 1313 | 1688 |

| Size mm | 46 | 46 | 46 | forty six | forty six | forty six | forty six | forty six | forty six | 46 |

| No-load velocity rpm | twenty five | 20 | twelve | eight period5 | 6 period5 | five | four | three period5 | 2 period5 | two |

| Rated pace rpm | twenty | sixteen | ten | six period5 | 5 | four | 3 | three | 2 | 1 period5 |

| Rated torque kg periodcm | 1 period5 | one period5 | one period5 | two | two | three | three | eight | 10 | ten |

| Max periodmomentary tolerance torque kg periodcm | 3 | 3 | three | five | 5 | 8 | 8 | 15 | 15 | 15 |

Solution Software

| Other Purposes colon | |

| Enterprise EPTTs colon | ATM comma Copiers and Scanners comma Currency EPT comma Stage of Sale comma Printers comma Vending EPTTs period of time |

| Food and EPTTrage colon | EPTTrage Dispensing comma Hand Blenders comma Blenders comma Mixers comma Coffee EPTTs comma Foods Processors comma Juicers comma Fryers comma Ice Makers comma Soy Bean Milk Makers period of time |

| Residence EPTTrtainment and Gaming colon | Gaming EPTTs comma Video clip Video games comma EPTal Disk Drives comma RC and EPTT Toys period |

| Home EPTnologies colon | Home EPT comma Air Purifiers and Dehumidifiers comma Variety Hoods comma Washers and Dryers comma Fridges comma Dishwashers comma EPTr Care comma Whirlpool and Spa comma Showers comma EPT Metering comma Coffee EPTTs time period |

| Lawn and XiHu (West EPT) Dis.Hu (West EPT) Dis.den colon | Lawn Mowers comma Snow Blowers comma Trimmers comma Leaf Blowers period of time |

| Personal Care colon | Hair Cutting comma Hair Care comma Massagers time period |

| EPTT Tools colon | Drills and Drivers comma Sanders comma Grinders comma PoEPTTrs comma Saws period of time |

| Camera and EPTal colon | Movie comma Cameras comma Projectors period of time |

EPTT amp Shipping and delivery

EPTT colon one carton EPTT comma a hundred items for each box interval

EPT time colon

DHL colon 3-5 doing work daEPTT semi

UPS colon 5-seven working days semi

TNT colon 5-7 operating days semi

FedEx colon seven-9 doing work days semi

EMS colon twelve-fifteen functioning times semi

By Sea colon Relies upon on which region

Our EPTT

TT EPT lparHK rpar EPTT Co period comma Ltd has been EPTTizing in micro motors comma EPT motors and their respective elements because 2000 time period

Our items are broadly utilized in EPTTrtainment techniques comma automobiles comma home and EPTT EPTs and equipment and numerous other individuals interval Our products are reliable and EPTT-long lasting comma and backed by years of knowledge interval We export 98 percnt of our output globally interval

By EPTaging our challenging-received popularity for honesty comma dependability and top quality comma TT EPT aims to proceed as a pioneer in the income overEPTT by in search of EPTT associates time period If your firm is an conclude-consumer of micro-motors comma a distributor or an agent comma please get in touch with us period of time We search EPTT to currently being capable to operate together with you in the around EPT period of time

FAQ

Q colon How to purchase quest

A colon deliver us inquiry rightEPT EPT our quotation rightEPT negotiate particulars rightEPT affirm the sample rightEPT indication deal soldeposit rightEPT mass production rightEPT cargo ready rightEPT equilibrium soldelivery rightEPT even more cooperation period

Q colon How about Sample purchase quest

A colon Sample is obtainable for you interval make sure you contact us for specifics time period Speak to us

Q colon Which delivery way is avaliable quest

A colon DHL comma UPS comma FedEx comma TNT comma EMS comma EPTT Publish commaSea are available periodThe other shipping waEPTTare also obtainable comma please make contact with us if you require ship by the other shipping and delivery way time period

Q colon How EPTT is the provide quest

A colon Devliver time relies upon on the amount you order time period typically it requires fifteen-twenty five operating times period

Q colon My bundle has lacking merchandise interval What can I do quest

A colon Make sure you get in touch with our assist team and we will confirm your orEPTTwith the deal contents periodWe apologize for any inconveniences period

Q colon How to validate the payment quest

A colon We accept payment by T solT comma PayPal comma the other payment waEPTTalso could be approved commaPlease make contact with us before you pay out by the other payment approaches time period Also 30-fifty percnt deposit is accessible comma the harmony income should be paid ahead of shipping time period

in Mogadishu Somalia sales price shop near me near me shop factory supplier 12V 24V 30W 60rpm Low Rpm DC Worm Gear Motor manufacturer best Cost Custom Cheap wholesaler

We will supply greatest services and higher quality goods with all sincerity. In this way, our merchandise have ongoing to obtain marketplace acceptance and customers gratification over the previous number of several years. EPG will constantly adhere to it company spirit of becoming sensible, revolutionary, efficient and superb to make the top international transmission travel.

12V 24V 30W minimal rpm dc worm EPT motor

one.Merchandise Description

59mm diameter higher quality12V/ 24V DC worm EPT motor

one.size:Diameter 59mm

two.existence time:5000 hours

three.materials:copper or plastic

59mm diameter large high quality 12V 24V DC WORM Equipment MOTOR

Application:

welding EPT, EPT EPT, diamond EPTry, workplace EPT tools, resort EPT, antomated EPT and so on.

EPT Voltage: DC12V, 24V,42V,48V,90V,110V ,300V

EPT Rated EPT:15W, 25W,30W,45W,65W, 95W,120W,50W,180W

EPT no-load Velocity:15RPM, 30RPM,60RPM,80RM,120RPM,150RPM,180RPM,200RPM,220RPM.

|

Model |

VOTAGE (V) |

EPT (W) |

NO-LOAD Speed(RPM) |

NO-LOAD Present(A) |

LOAD Pace(RPM) |

LOAD Recent(A) |

LOAD TORQUE(N.M) |

RATIO |

MOTOR Size |

|

59ZYT |

twelve |

30 |

fifteen plusmn2 |

le1.2 |

12 plusmn2 |

le4.five |

ge4. |

one:70 |

80 |

|

59ZYT |

24 |

30 |

fifteen plusmn2 |

le1.two |

twelve plusmn2 |

le4.five |

ge4. |

1:70 |

80 |

|

59ZYT |

24 |

fifty |

36 plusmn2 |

le1.2 |

32 plusmn2 |

le6.five |

ge8. |

one:70 |

eighty |

|

59ZYT |

twelve |

thirty |

65 plusmn3 |

le1.two |

sixty plusmn3 |

le5.5 |

ge6. |

1:56 |

eighty |

|

59ZYT |

24 |

30 |

65 plusmn3 |

le1.two |

sixty plusmn3 |

le5.five |

ge6. |

one:56 |

80 |

|

59ZYT |

forty eight |

30 |

sixty five plusmn3 |

le1.2 |

60 plusmn3 |

le5.5 |

ge6. |

1:56 |

eighty |

|

59ZYT |

42 |

thirty |

a hundred thirty plusmn5 |

le1.5 |

100 plusmn5 |

le6.five |

ge4. |

one:28 |

eighty |

|

59ZYT |

forty two |

30 |

150 plusmn5 |

le1. |

one hundred thirty plusmn5 |

le6.5 |

ge4. |

one:28 |

eighty |

|

59ZYT |

24 |

thirty |

a hundred and eighty plusmn5 |

le1.two |

150 plusmn5 |

le6.five |

ge4. |

one:28 |

80 |

|

59ZYT |

24 |

30 |

210 plusmn3 |

le1.5 |

one hundred eighty plusmn5 |

le6.five |

ge4.two |

1:28 |

80 |

Remarks: We also manufactue goods in accordance to customer’s needs.

two.Production Movement

three.Business Data

In latest 10 a long time, EPTry has been committed to the manufacture of the motor goods and the principal products can be classified into the adhering to sequence, namely DC motor, DC EPT motor, AC motor, AC EPT motor, Stepper motor, Stepper EPT motor, Servo motor and EPT actuator collection.

Our motor products are widely used in the fields of aerospace business, automotive market, finXiHu (West Lake) Dis.Hu (West Lake) Dis.al gear, EPT EPT, EPT EPT and robotics, healthcare gear, place of work equipment, EPT EPTry and EPT industry, giving consumers reputable tailor-made answers for driving and managing.

four.Our Companies

1). EPT Support:

|

Quick Reply |

All enquiry or e-mail be replied in 12 hrs, no delay for your organization. |

|

Expert Team |

Inquiries about items will be replied skillfully, exactly, best guidance to you. |

|

Brief EPT time |

Sample or tiny orEPTsent in 7-15 times, bulk or tailored orEPTabout thirty days. |

|

Payment Selection |

T/T, Western Union,, L/C, etc, easy for your company. |

|

Ahead of shipment |

EPTke photographs, send to clients for affirmation. Only verified, can be delivered out. |

|

Language Option |

Aside from EPT, you can use your personal language by e mail, then we can translate it. |

2). Customization Support:

EPT specification(no-load pace , voltage, torque , diameter, sound, existence, testing) and shaft length can be tailor-manufactured in accordance to customer’s requirements.

five.Package amp EPT

Best China manufacturer & factory high quality 12v 2000rpm 500w gear motor nmrv50 worm gearbox with 24v dc servo motor supplier With high quality best price

EVER-POWER GROUP CO., LTD. IS SPECIALIST IN MAKING ALL KINDS OF MECHANICAL TRANSMISSION AND HYDRAULIC TRANSMISSION LIKE: PLANETARY GEARBOXES, WORM REDUCERS, IN-LINE HELICAL GEAR SPEED REDUCERS, PARALLEL SHAFT HELICAL GEAR REDUCERS, HELICAL BEVEL REDUCERS, HELICAL WORM GEAR REDUCERS, AGRICULTURAL GEARBOXES, TRACTOR GEARBOXES, AUTO GEARBOXES, PTO DRIVE SHAFTS, SPECIAL REDUCER & RELATED GEAR COMPONENTS AND OTHER RELATED PRODUCTS, SPROCKETS, HYDRAULIC SYSTEM, VACCUM PUMPS, FLUID COUPLING, GEAR RACKS, CHAINS, TIMING PULLEYS, UDL SPEED VARIATORS, V PULLEYS, HYDRAULIC CYLINDER, GEAR PUMPS, SCREW AIR COMPRESSORS, SHAFT COLLARS LOW BACKLASH WORM REDUCERS AND pto shaft, agricultural gearboxes SO ON.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Product name:

-

NMRV wormCustomer Support EPG is committed to offering world class customer support, for both current and legacy products, putting you, our customer, at the heart of everything we do, we really are with you at every turn. gear reducer

- Housing Material:

-

Aluminium alloy

- Material:

-

copper

- Warranty:

-

1-2 Years

- Ratio:

-

5-100

- Bearing:

-

NSK Bearing

- Certificate:

-

ISO9001

- Output torque:

-

2.6-1195N.M

- Output speed:

-

0.64-350rmp

- Intput speed:

-

750~3000rpm

Packaging & Delivery

-

Lead Time

: -

Quantity(Bags) 1 – 3 4 – 5 >5 Est. Time(days) 5 10 To be negotiated

Online Customization

Our factory has obtained the certificate of China’s Farm Machinery Products Quality Authentication promulgated by the Farm Machinery Products Quality Authentication Centre of China.

Product Description

NMRV NRV SERIES WORM GEAR SPEED REDUCER

According to European standard of similar product,we adopt high-quality artificial oil,imported famous brand seal parts and manufacture technology to produce square multi-placed reductor. Feature beautiful appearance,easy installation,compact structure,low noise and high efficiency.

NMRV worm gear reducer absorbs advanced technology at home and abroad. It has a novel and unique “square box” external structure. The box is beautiful in shape and is made of high quality aluminium alloy by die casting.

NMRV RV series structure drawing

NMRV Model & Marker

|

NMRV-063-30-VS-F1(FA)-AS-80B5-0.75KW-B3 |

|||

|

NMRV |

Worm geared motor |

||

|

NRV |

Worm reduction unit |

||

|

063 |

center dictance |

||

|

30 |

Reduction ratio |

||

|

VS |

Double input shaft |

F1(FA) |

Output flange |

|

AS |

Single output shaft |

AB |

Double output shaft |

|

PAM |

Fitted for motor coupling |

80B5 |

Motor mounting facility |

|

0.75KW |

Electric motor power |

B3 |

Mounting position |

NMRV NRV SERIES WORM GEAR SPEED REDUCER FEATURES:

● The weight of the NMRV reducer is relatively light. The shell is made of aluminium alloy. It has the advantages of light weight, superior strength, exquisite appearance, high heat dissipation performance, long service life, no noise and so on. It is easy to connect with the motor.

● NMRV reducer is a more practical transmission equipment, and in the appearance design and its integration are more in line with the needs of the public than other types of reducers.

●The application field and popularity of the RV reducer made of aluminium alloy are even better than other types of reducer. It is a kind of reducer with high practicability, and also a combination of advanced technology at home and abroad.

● NMRV reducer is very convenient to connect with ordinary motor, CVT, flange electromagnetic clutch brake unit, and does not need coupling. Suitable for all-round installation, and the output torque is relatively large, work fairly smoothly and so on.

NMRV NRV SERIES WORM GEAR SPEED REDUCER MOUNTING DIMENSIONS

Single Step Worm Gear Reducer

Output Flange Mounting Dimensions

Torque Arm

HIGH QUALITY OUTPUT SHAFT

New standard axle, multi-precision machining, through rigorous dynamic and static balance test, to ensure low noise and smooth operation of reducer.

PRECISION BEVEL GEAR

worm and gear: The gears are made of 10-1 tin bronze (with high strength, corrosion resistance and excellent casting properties).

Worm adopts 20CR:carburized alloy structural steel (with high strength, hardenability, wear resistance).

High Speed BeariIn our sales program we offer standard and wide-angle PTO drive shafts. Regarding the customers’ needs there are different sizes, lengths and safety elements (clutches) available.ngs and SKF Seals:Use synthetic oil (friction agent: reduce temperature rise, reduce friction).

HIGH QUALITY SHELL MATERIAL

High-quality aluminium alloy casting:lightweight, rust-free, high output torque.

Military manufacturing technology:smooth transmission, low noise, good heat dissipation effect.

Fine appearance:beautiful and durable, small size, suitable for all-round installation.

Our Company

Zhejiang provice EPT – one of the Biggest Transmission manufactrer in China GEAR TECHNOLOGY CO., LTD

Our company is located in the city of HangZhou ( Beautiful city where West lake located ) , Zhejiang provice Province of China.

We handle the products of power transmission, our lines mainly cover series products in speed reducers, gearboxes , associated electricial motors and other power transmission accessories. Based on the versatile functions, our products can be utilized in many fields: machines of waste water treatment, dredgers, chemical industry, cranes, metal working mills, conveyors, paper industry, cement industry, cableways and so on.With the excellent quality and reasonable price , our products enjoy a good reputation from customers and the peers all over the world.

Furthermore, the R&D investment are annually increasing for the purpose of better meeting the new demands of our customers and adapting the new tendency of the industry.

Depending on the principles of honestly operating and mutual benefit, We sincerely look forward to cooperating with you.

Application area

NMRV NRV worm gear speed reducer.

It is widely used in many fields such as metallurgy, mine, printing, chemical industry, textile, foodstuff, medicine, rubber and plastic,etc.

Packing&Transportion

PACKING AND TRANSPORTION

●Packaging: In order to ensure the integrity of product appearance, we will choose cartons, wooden pallets and wooden pallets according to customer needs.

●Delivery time: Each reducer is manufactured and tested in accordance with strict and fixed procedures to ensure that the quality is correct before leaving the factory and delivery on time.

●Transportation mode: We will choose the most suitable mode of transportation for our customers according to the weight and size of the goods. We can also choose the mode of transportation according to the needs of our customers.

●Receiving and after-sales service: After receiving the goods, please check whether they are in good condition. We will provide customers with perfect after-sales service.

FAQ

Q1: Are you a trading company or amanufacturer?

A: We are a manufacturer in Zhejiang provice Province, China. Our company owns the ability of manufacturing, processing, designing and R&D. We welcome your visit.

Q2: How we select models and specifications?

A: According to the specific details of the demands from the part of enquiry, we will recommend the products’ models upon synthesizing the factors of field of products usage, power, torque arm and ratio…

Q3: How is your price? Can you offer any discount?

A: Our prices are always competitive. If the customer can place a large order, we surely will allow discount.

Q4: How long should I wait for the feedback after I send the enquiry?

A4: We will reply as soon as possible, 12 hours at most.

Q5: What is your product warranty period?

A: We have the certifications of ISO9001,CE, SGS.

Q6: What industries are your gearboxes being used?

A: Our gearboxes are widely applied to metallurgical equipment, mining equipment, automation equipment, food machinery, packaging equipment, tobacco equipment and so on.

GS use of a worm gear shop China in Sylhet Bangladesh 24V 60W 80mm Brushless DC Motor with top quality

We – EPG Group the biggest worm gearbox, couplings and gears factory in China with 5 different branches. For more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778083988828

/

60W 80mm dc brushless motor

Introduction

Brushless DC motor (BLDC) is made up of motor and driver, which is a kind of typical product of mechanical and electrical and electrical integration. It is high regarded by market as its small volume, low noise, high efficiency, wide range of speed control and steady wor ept state with less inaccuracy.

Specifications

1. Dimensions of device: 80mm

2. Rated Power: 40W

3. Voltage: 24, 36, 48V

4. CCC, CE, UL, CU

5. Motor voltage, power and speed will be customized according to your request under the allowed circumstance of adoptable dimension.

Greensky’s Advantage

On the site you can find a range of renewable products including ac/dc motor, induction motor, reversible motor, brake motor, speed control motor, ac angel motor, gear motor, planetary gearbox, worm gearbox and their relevant components.

If you have any other questions, please feel free to contact us.

| Model | Voltage V |

Rated Power W |

No-load Parameters | Load Parameters | Motor Life H |

Motor Weight kg |

|||

| Speed RPM |

Current A |

Speed RPM |

Torque N.m |

Current A |

|||||

| 4BLD60-24 | 24 | 60 | 3300 | MAX0.50 | 3000 | 0.19 | 3.2 | >5000 | 1.2 |

| 4BLD60-36 | 36 | 60 | 3200 | MAX0.35 | 3000 | 0.19 | 2.1 | >5000 | 1.2 |

| 4BLD60-48 | 48 | 60 | 3200 | MAX0.25 | 3000 | 0.19 | 1.6 | >5000 | 1.2 |

/

The use of original equipment manufacturer’s (OEM) part numbers or trademarks , e.g. CASE® and John Deere® are for reference purposes only and for indicating product use and compatibility. Our company and the listed replacement parts contained herein are not sponsored, approved, or manufactured by the OEM.

/

High worm and roller steering gearbox manufacturer China in Bournemouth United Kingdom Quality 24V DC Geared Motor Electric with Gear Ratio 61: 1 with top quality

We – EPG Group the biggest worm gearbox, couplings and gears factory in China with 5 different branches. For more details: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778083988828

/

General information

- Aluminum die-cast gearbox

- Rolled steel housing construction

- Built-in EMC components

- Hall sensor feedback available

- Various output shaft extension are available

- Reduction ratio: 61:1

- Nominal efficiency: 25 – 70%

Specification

| Specification | MB083HB101-WH61 |

| Rated Voltage | 24 VDC |

| Rated Current | 9 A Max |

| Rated Torque | 8 Nm |

| Rated Speed | 50±10%RPM |

| Static Torque | 18 Nm |

| Starting Torque | 70 Nm |

| Current | 16A at 26 Nm |

| Duty Cycle | S2 5min |

| Insulation Class | B |

| Gearbox Specification | |

| Ratio | 61:1 |

| Noise | Less than 65dB |

Other gear ratio is avaiable at special production

Packaging & Shipping

1, Waterproof plastic bag packed in foam box and carton as outer packing.

2, Export wooden box packaging for products.

Company Profile

- Originally motor division of CMEC HangZhou- China National Machinery & Equipment Imp & Exp HangZhou Co.,Ltd., one of TOP 20 stated owned Machinery Group

- Privately owned Ltd company since 2000: HangZhou Junhong Automation Technology Co. Ltd.

- Exmek Electric —Registered Brand Name

- Business: Design and manufacture of motion control products and components

- Highly qualified personnel

- UL, CE, RoHS certification

- ISO 9001, ISO 14000

Company Capabilities

- Modern Motor Design and Manufacture

- Part Set Design and Manufacture

- Magnetic Design Software-Motorsolver

- Molding

- Shipping world wide

Why Exmek Electric

- Open for general discussion and questions

- Time to market or theatre of operations can be substantially reduced

- Talented team of engineers providing innovative technical solutions

- One stop “supplier” and complete sub-system

- Quality products provided at competitive low cost

- Ability to ship world wide

- On time delivery

- Training at Customer locations

- Fast service on return and repair results

- Many repeated customers

Applications:

Use for swimming pool, automotive, semiconductor, chemical & medical, industrial automation, power tool, instrument, measuring equipment, office automation, various OEM application.

We are open for general discussion and questions. Contact us now!

Exmek Electric, your long-term reliable partner.

/

The use of original equipment manufacturer’s (OEM) part numbers or trademarks , e.g. CASE® and John Deere® are for reference purposes only and for indicating product use and compatibility. Our company and the listed replacement parts contained herein are not sponsored, approved, or manufactured by the OEM.

/